Custom stainless steel miniature parts

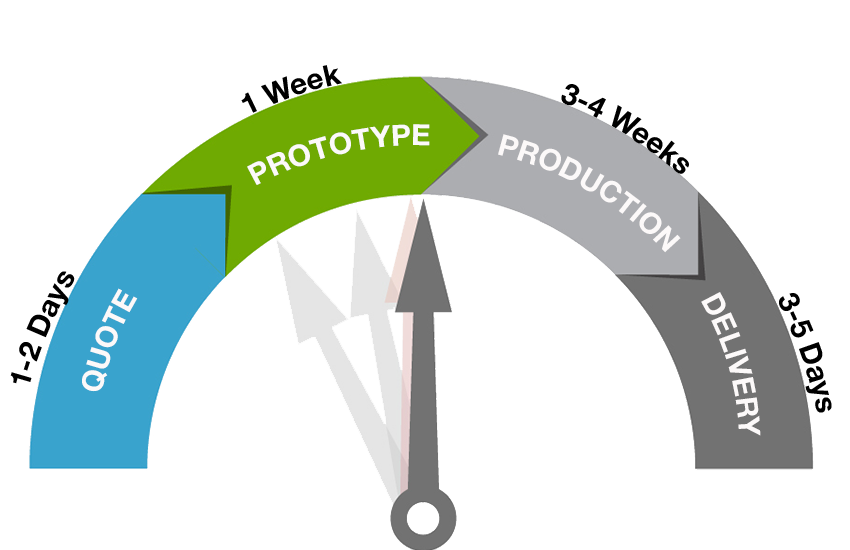

in as little as 30-45 calendar days

After 50+ years in the manufacturing industry, we know how to eliminate waste.

By implementing Six Sigma process improvement training across our company, we’ve optimized our systems to bring you aerospace-quality stainless steel parts, produced in record time.

%

Part Acceptance Rate

%

On-time Delivery

Million Parts Per Year

Get a Speedier Quote

Consider these requirements before you make the call:

Application

What type of system will it be used in?

Fluid

The type of fluid to be purified.

e.g. SAE 45 oil, air, coolant

Micron Rating

The size of the smallest particle that will need to be strained.

Dimensions

Length, width, height, diameter

Initial Quantity Needed

The quantity needed after a successful prototype is delivered.

Estimated Quantity Per Year

Initial year’s estimated production (include subsequent year estimate if available).

Just-In-Time Delivery

Kanban Efficient Inventory Replenishing

Our high-volume customers with predictable replenishment needs gain efficiency through our lean and just-in-time (JIT) programs. We evaluate each customer on a case-by-case basis to determine whether producing and stocking their parts in advance can help add profitability to their production cycles.

Customers utilizing our Kanban scheduling can receive filters in as little as 5 business days.

Success Depends on Smart Partnerships

Contact us today to put over 50 years of experience to work for you.