Stainless Steel Filters

Customize 10 Factors for a Perfect Fit.

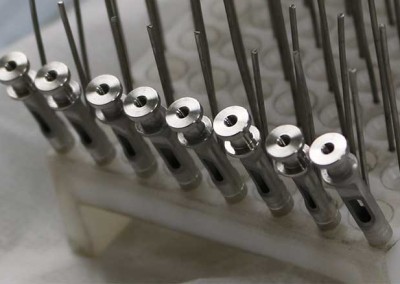

Recco Filters produces filters, from the size of a hand – down to the size of a fingertip,

that are designed to catch chips, burrs, and wear particles before they compromise your fluid system.

Our Stamping, Shearing, Micro-Welding, and CNC Manufacturing capabilities

produce small filters, strainers, baskets, and screens to your exact specifications.

- Optimum Flow Rates

- Precise Aperture Size Distribution

- High Levels of Stability

- Rigidity

- Advanced Abrasion Resistance

- No Particle Detachment

- Easy to Clean

- Good Plasticity

- Chemical and Thermal Resistance

- Smooth Surface Structure

- Advanced Reliability

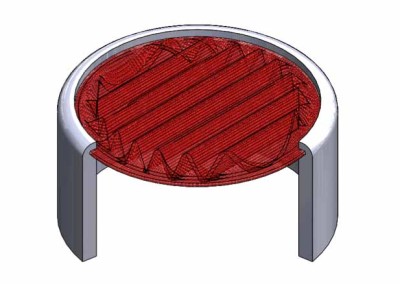

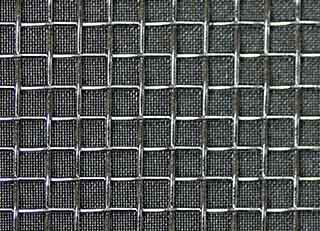

1. WEAVE

Affects flow rate, micron-rating, and open area.

Coarse

Medium

Fine

Ultra-fine

2. CONSTRUCTION

Options to withstand high-temperatures, varied chemicals, and high pressure environments.

Sintered Mesh

A cost-effective filter media in weaves down to >1 micron absolute.

Corrosion Resistant Stainless Steel (CRES) + DFARS-compliant sourcing upon request.

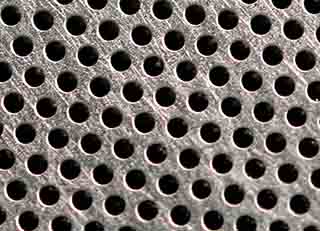

Photo-etched Media

Provides a smooth surface and increased open area.

Corrosion Resistant Stainless Steel (CRES) + DFARS-compliant sourcing upon request.

Laminated Media

2-3 layers; coarse mesh for stability and finer mesh for filtration.

Corrosion Resistant Stainless Steel (CRES) + DFARS-compliant sourcing upon request.

The Extra Mile: Our aerospace filter media is tested by independent laboratories to confirm the alloy composition.

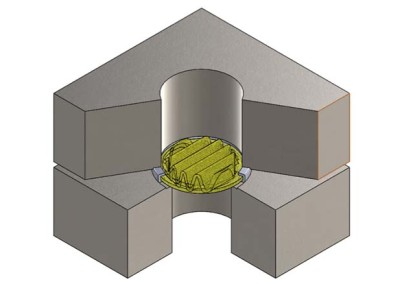

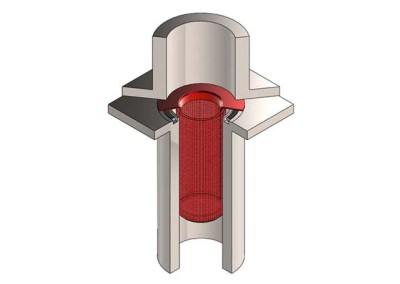

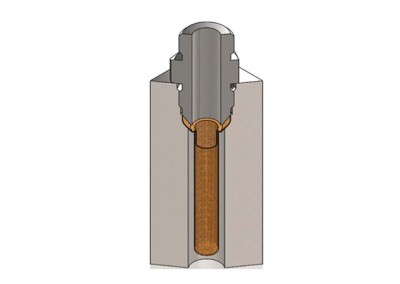

3. FORM FACTOR

Our most popular form factors.

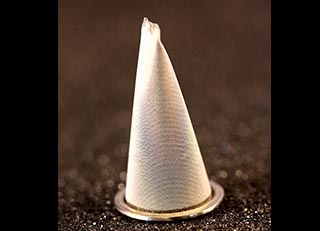

Dome Filters

Conical Filters

Disc & Pleated Disc Filters

Mesh Forms, Belts, and Straps

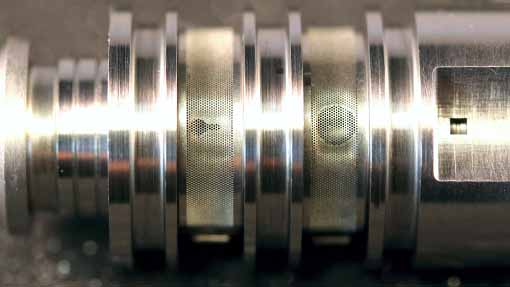

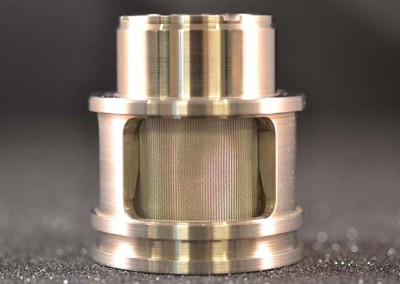

Cylindrical Filters

4. FLUID COMPATIBILITY

Our filters are compatible with most popular industrial fluids.

Hydraulic Fluid Filters

Fuel Filters

Freon Filters

Coolant Filters

Lubricant Filters

Water Filters

Cutting Oil Filters

Liquefied Propellant Filters

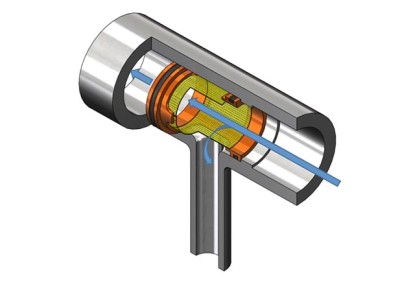

Custom Engineered Filter Housings

Our on-site CNC facility enables us to produce precision metal housings, end caps, fittings, and more to complete your finished product. Integrated CNC, welding, fabrication, and finishing facilities in one location gives us the dual advantages of shorter lead times and greater cost efficiency.

5. MATERIALS

Modify to meet the needs of your operating environment.

Stainless Steel Bar

Carbon Steel

Titanium

6. HOUSINGS

You don’t have to go to multiple suppliers to get finished parts – we machine your custom fittings and housings on-site.

Common Housing Styles

- Swaged In

- Connecting Bobbin

- Triple Union

- Flange

- Port Boss

- Tube Flare

- Wash Flow

7. MOUNTING

A custom mount designed to be a perfect fit.

8. FINISH

Smooth, clean, chemical-free surfaces.

Deburring

Polishing

Cleaning

Passivation

9. IDENTIFICATION

Crystal clear identification for receiving, inventory, and maintenance.

Laser Marking

Bar Coding

Individual Labeling

Dot Matrix Marking

10. PACKAGING + SHIPPING

Select how your parts are bagged + boxed for supply chain efficiency.

Individual Bagging

Boxing

Ship via UPS/FED EX

Beyond Filters

Looking for a supplier of small metal parts? Put our excellence in miniature manufacturing to work for you.

Porous Stainless Steel

Wire Cloth Mesh

Photo-etched Media

Steel & Titanium Sheets

Our On-Site Capabilities

Precision Metal Stamping

Stainless Steel Shearing

Resistance Welding

Custom CNC Fabrication

Success Depends on Smart Partnerships

Contact us today to put over 50 years of experience to work for you.